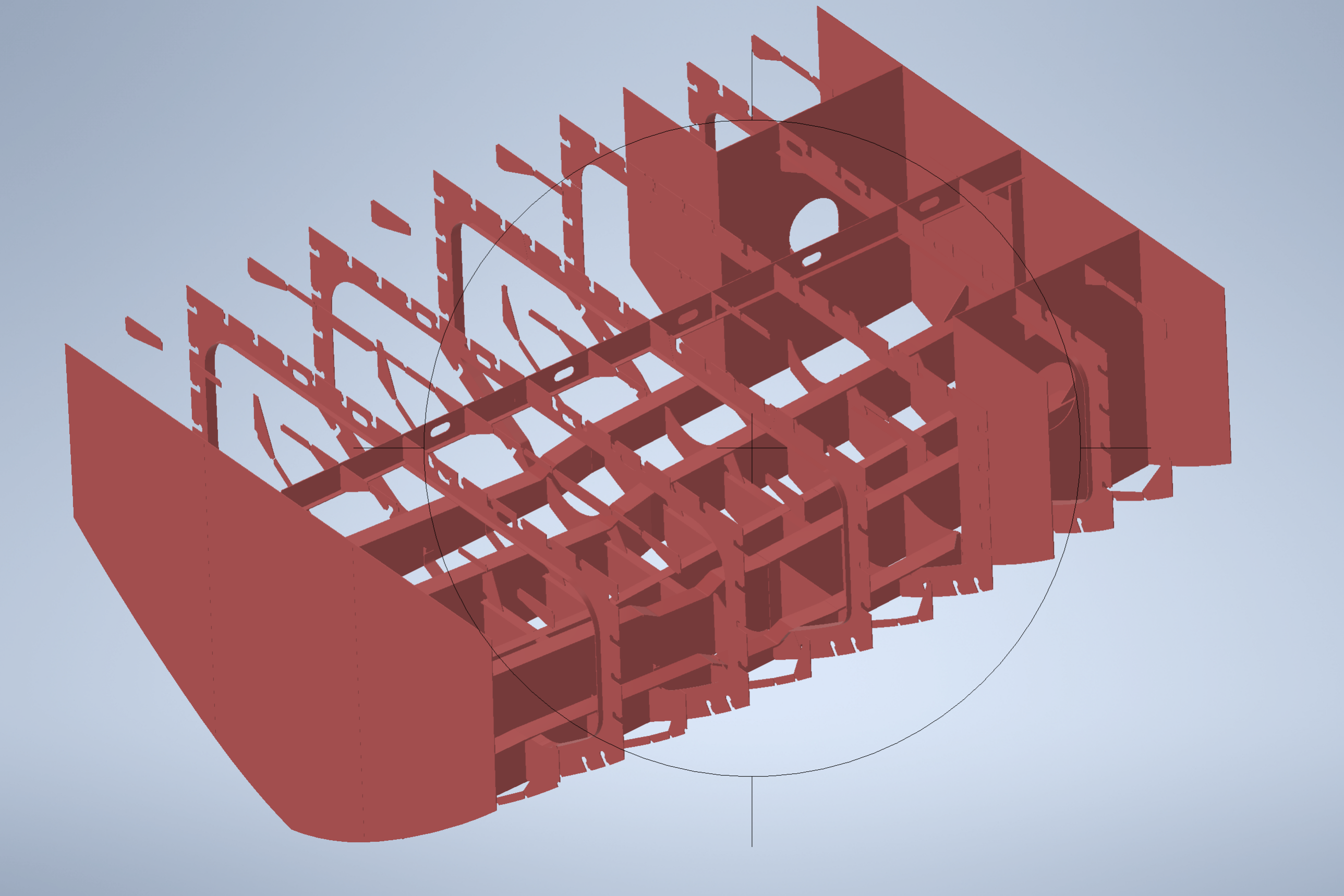

Plate nesting in shipbuilding offers several advantages that contribute to efficient production processes and cost savings:

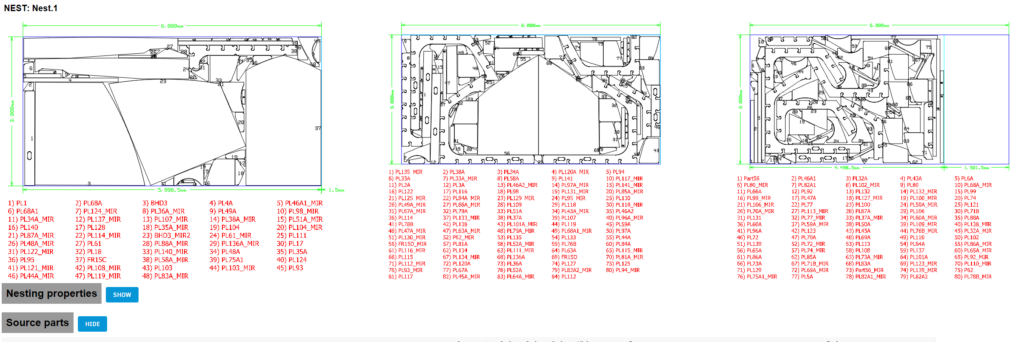

- Optimized Material Usage: Plate nesting software maximizes material utilization by arranging parts closely together on a metal plate. This minimizes waste and reduces the number of plates needed for construction, ultimately lowering material costs.

- Reduced Labor Time: By automatically arranging and optimizing the placement of parts on plates, nesting software streamlines the cutting process. This reduces manual labor time required for layout planning and cutting, leading to increased productivity and faster project completion.

- Improved Accuracy: Automated nesting ensures precise placement of parts, minimizing errors in cutting and assembly. This results in higher quality components and a more accurate final product, reducing rework and associated costs.

- Enhanced Flexibility: Plate nesting software allows for quick adjustments to design changes or production requirements. This flexibility enables shipbuilders to adapt to evolving project needs efficiently, without significant disruptions to the workflow.

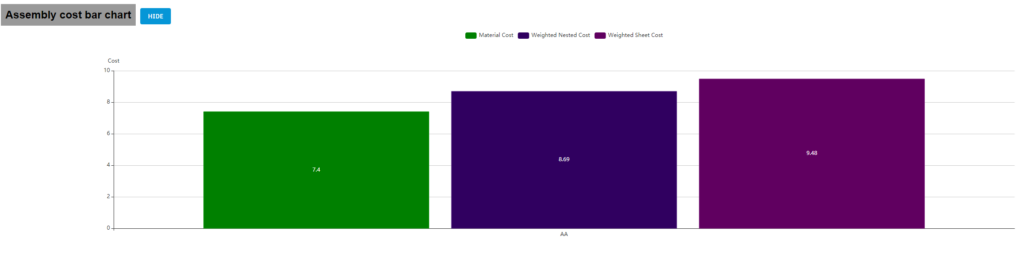

- Cost Savings: By minimizing material waste, reducing labor time, and improving accuracy, plate nesting ultimately leads to cost savings throughout the shipbuilding process. These savings contribute to the overall competitiveness and profitability of shipyards.

In conclusion, plate nesting in shipbuilding offers a range of benefits including optimized material usage, reduced labor time, improved accuracy, enhanced flexibility, and cost savings. Embracing this technology can significantly improve efficiency and competitiveness in the shipbuilding industry.